With EPS Thermal Insulation Board Coating How-To

13-03-2020

13:07

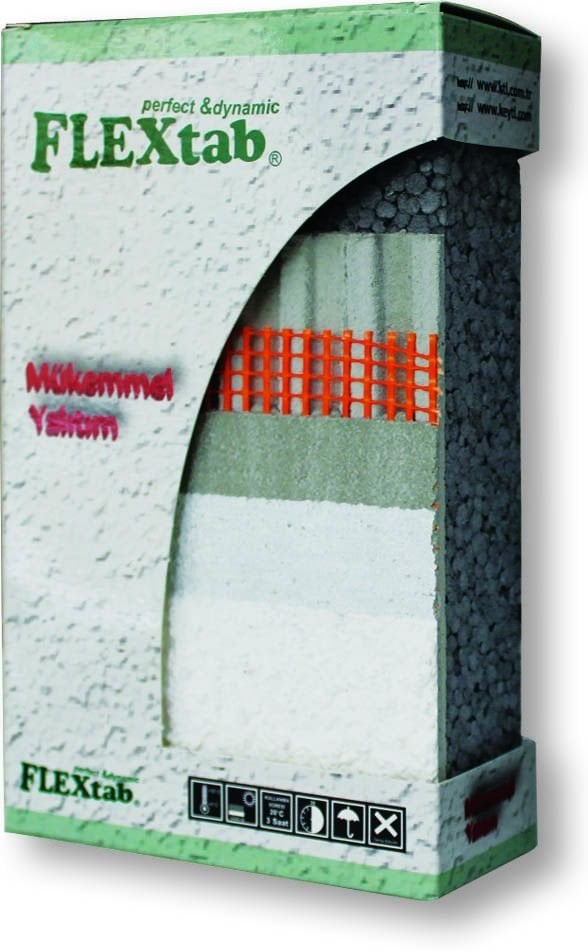

How-To of insulation jacketing system.

1-EPS thermal insulation and sheathing plates.

EPS insulation plates located in heat packs. Width: 50 cm Height: 1m Number plate a 0.5 m2 footprint.

| Thickness / Width / Height Cm | Pieces in the package | Covered Area m2 |

| 2 * 5 * 100 | 25 | 12.5 |

| 3 * 5 * 100 | 16 | 8 |

| 4 * 5 * 100 | 12 | 6 |

| 5 * 5 * 100 | 10 | 5 |

| 6 * 5 * 100 | 8 | 4 |

| 7 * 5 * 100 | 7 | 3.5 |

| 8 * 5 * 100 | 6 | 3 |

| 10 * 5 * 100 | 5 | 2.5 |

How many m2 of space can be determined according to the thickness of a packet in the above table. First, how many m2 of space, let us decide that we want to do with the few cm thick sheet. EPS thermal insulation board with a thickness of for example 5 cm yapacaksak 100 m2. Because we know 5 cm in thickness of a packet to be obstructed area of 5 m2, 20 packs of EPS thermal insulation board (Styrofoam) is required to take. There thicknesses and the options in each of the following link plates located EPS thermal insulation board.

EPS thermal insulation board have to be attached to surface insulation. Thermal insulation board should be adhesive. This insulating adhesive mortar has the 25 kg package. from 4.5 to 5 kg per m2 is spent. I.e., an area of 5 m2 is covered with a bag. For example, an area of 100 m2 is required to be 20 bag. You can find the link below.

we stuck to the wall with the sheet with a heat sealing adhesive mortar has to be secured by wrapping dowels. Each plastic sheathing 6 dowels per m2 future application form is required. 2-3-4 cm in thickness is enough for the slabs 10 cm dowel. 12 cm, 5-6 cm thick plastic dowel plates. 7-8 cm to 14 cm dowel plates. 10 cm to 16 cm dowel plates must be used. Usually plastic dowels 500 / bag packed and ready to return as conditions are. Options and this information appears in the description section. For example, 6 * 100 = 600 is used for an area of 100 m2 dowel. In this case the package must be taken at least one dowel. You can find Anchor link below.

After the plugging is done, the above insulation of EPS thermal insulation board with a layer of plaster mortar plastering should and should continue between the wrapping nets inside then coating is carried out again. Consumption of thermal insulation mortar plastering is about 5 kg per m2. 25 kg packaging with a bag that is an area of 5 m2 coated. For example, 20 for an area of 100 m2 bag must be obtained from this product. You can find the link below.

Plastering mortar cracks to occur while said reinforcement mesh to be used. Usually 160 g / m2 fiber mesh are preferred. There is no importance of color. Plaster generally, at the nets: 1 Height: 50 m ie, a roll of 50 m2. Consumption that is 10% more thrust shares. I.e. a 100 m2 area 110 m2 are used. Buda is necessary to take at least two rolls. If possible, it should be taken 3 turnovers. You can find the link below Plaster Reinforcement net.

After plaster grid application is made, after 24 hours of standby time needed, it can be done in the application of decorative plaster. But before you can make decorative primer application. 150 g per m2 is adequate. I.e. 130 m2 can be done by a decorative lining 20 kg. an area of 100 m2 will be enough to get the bucket decorative lining.

After the decorative lining, some companies are making decorative applications liner application. After this operation proceeds to topcoat application plaster decorative plaster application. There is still 25 kg bags. 2.5-3 kg of 1 m2 is coated place. In this case, a bag, 8-9 m2 area is covered. For a wrapping area 100 m2 will be available for retrieval bag 11 decorative plaster. You can find the related link below.

After application of decorative plastering, painting should be done with silicone exterior paint. 350 to 450 g and 1 m2 is coated. A bucket 45 to 50 m2 exterior paint containers. In this case, at least two buckets for a wrapping area 100 m2 Silicone Exterior Paint should be taken. There link below.

In addition, window frames and corner profiles should be taken to mesh wall corners. Each length of 2.5 m in the corners here meshed corner profiles must be used. Generally jacketing is calculated by multiplying by 0.25 the place to be. So for 100 m2 to 100 * 0.25 = 25 m mesh corner profile is required. Buddha 10 mesh corner profile for each 2.5 m in length that one would be enough for 100 m2. According to the corners of walls and window can be increased or decreased. You can find the link below.

These products sometimes windowsill outside sheathing extension profile, fuga profile, help may be needed in products such as pipettes profile. You can find them in batches of these products contained the following link.

Above Insulation System EPS (styrofoam) general information on the requirements of a system are provided with. Each step must be respected institution in the waiting period. It should be noted that the application temperature of 5 C to 25 C.